Everyone knows them: savings campaigns from supermarkets or petrol stations for experiences, products or toys. In marketing terms, they are called loyalty programs and they involve a lot worldwide. In money, but certainly also in materials and therefore in raw materials. The Breda company Craze is a major player in loyalty programs and, in collaboration with the Biopolymer Application Center (BAC), is going for a large-scale sustainability battle in the field of raw materials use. The magic word? Biopolymers.

We spoke to Jeroen de Bruin, director of the Kids Promotions business unit at Craze. He explains the reason for the research that is now being conducted: “Within our business unit, we produce millions of pieces of ‘collectables’ per promotion. Mostly they are made of plastic and although they are of course not intended to be thrown away, we do put many small plastic items into circulation. We want to reward children with fun and unique toys in the short term, but we obviously do not want this to be at the expense of long-term quality of life, we would like to take steps to reduce the impact on the environment. ”

BAKERS

Consumer awareness about sustainability issues is growing rapidly, De Bruin agrees. Everyone can still remember the fuss about Albert Heijn’s hamster balls and, one month later, the “Biscuit bakers” made of synthetic plastic.

“Consumers now know very well that plastic is harmful to the environment and they are opposed to waste. The big problem, however, is that nobody is able to produce large quantities in bioplastic affordably and quickly. ”

OWN BIO COMPOUND

“Our assignment now consists of two parts. In the short term, we want to start immediately with the production of our collectibles based on an existing biopolymer and we want to map out the technical consequences this has for the production process. In the longer term, we want to move towards our own biopolymer that is also industrially compostable, ”explains De Bruin.

Craze hopes to eventually be able to make products that can simply be thrown in the green bin at the end of their life. “We were looking into the field of bioplastic and that is how we ended up at the Breda Center of Expertise Biobased Economy.” according to De Bruin. “After an initial meeting – in which we immediately received a lot of tips and advice – we actually immediately stated that we wanted to work together with the BAC. The knowledge we are looking for is available and we are pleased that we are really personally advised by people who understand how our production processes work. ”

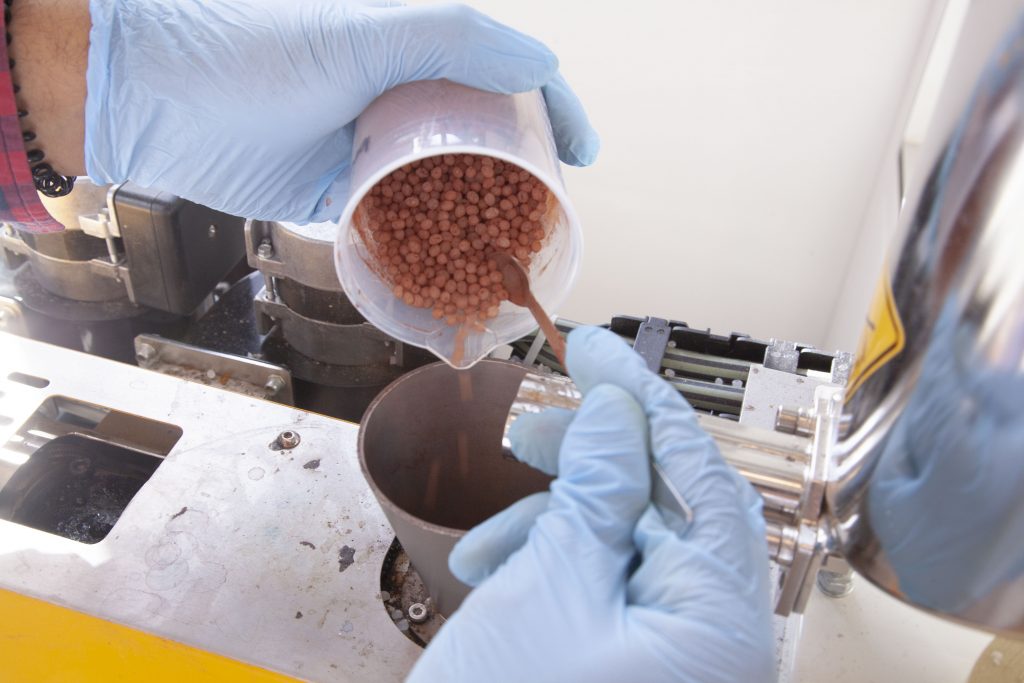

The collaboration with the BAC has already yielded immediate results for Craze. “We have now reached the point where we will be able to produce in bioplastic as early as this year.

We have optimized our production process with the BAC and – taking into account the technical limitations of biopolymers – we have come up with unique premiums that can be produced well, quickly and affordably ”. This production also takes place in the Netherlands, so that CO₂ emissions from transport also go down.

Future plans

There are still plenty of actions to be taken in the near future. Craze also wants to achieve a CO₂ reduction in savings campaigns where consumers can save for high discounts on (A-brand) products. De Bruin: “We think that we can replace some plastics – in both the products and the packaging – fairly easily with biopolymers”.