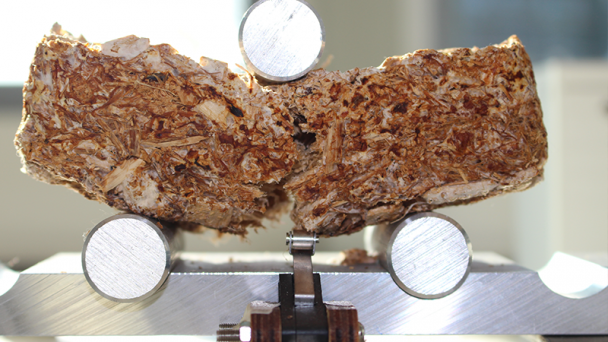

In the “Building On Mycelium” project, Avans University of Applied Sciences, HZ University of Applied Science and partners are investigating how locally available organic waste streams can be used to produce mycelium biocomposites, with properties that make them suitable for the construction sector. In this project the emphasis will be on (studying) the manufacture of furniture or interior panels.

The greatest challenge of this century is to turn our economy into an ecologically sustainable system. This can be done by significantly reducing the consumption of energy and raw materials. 40% of total European energy consumption and about 45% of CO2 emissions are related to the construction and use of buildings (EC, 2015), of which almost half embodies energy in materials. The construction sector is also responsible for 40% of raw material consumption worldwide.

Mycelium as a solution

A solution with a lot of potential is based on mycelium. Mycelium is the “root network” of mushrooms, which acts as a natural glue to bind biomass. Various organic residual flows such as straw, sawdust or other agricultural waste can be used as a nutrient medium. These mycelium composites were only invented ten years ago, but because of their durability and unique properties, there is already a lot of interest in the industry.

The production of these composites has a relatively low energy consumption, because mycelium grows at low temperatures (25-30 ° C). For example, the production of mycelium “foam” uses almost ten times less energy than the production of polystyrene foam (styrofoam). Other advantages are that mycelial biocomposites are completely natural, non-toxic, biological materials that can be grown locally and composted after use (Jones et al., 2018).

Consortium

Avans has already carried out several initial studies that indicate promising possibilities for the development of mycelium composites based on local residual flows of biomass. The “Building on Mycelium” project now brings many more partners together, including processors of agricultural materials, designers, material producers and end users. The connecting factor is that all companies regard mycelium composites as a promising material and in this way can make high-quality use of their residual flows or use the materials for their company.

The leading question for the partners is to provide data on the material properties of these mycelial biocomposites to determine whether the composites are suitable for use in their applications. Therefore, in the project “Building on Mycelium” we will study the use of local agricultural residues in mycelium composites, test the different material properties, perform an initial evaluation of a design and analyze the economic and environmental aspects.

Avans University of Applied Sciences and the industrial partners will collaborate on this project with the microbiology department of Utrecht University and SME Mogu Srl (Italy), who are among the leading experts in the field of mycelial materials. Hogeschool Zeeland will supplement the consortium with knowledge about processing techniques.

“Building on Mycelium is co-financed by the SIA, part of the Netherlands Organization for Scientific Research (NWO). “

This project is finished. You can find the results in the Whitepaper below:

Martijn Zieverink inaugurated as Biobased Transitions professor

Whitepaper: Nature-Inclusive Principles

MycEoLA: a second life for mycelium biocomposites

Protein of Columbus

BIO-CAPPP

Energy Education

BIO-CAPPP

GESCHIKT: energy transition on business parks

Rapid Renewable Materials: the next step in sustainable construction.

Mycelium on Board

From orange waste to a green future

Blueprint of fungal genomes

BioGov.net

Water-resistant mycelium composites

Sustainable Particle Board

Circular Emergency Shelters

FACET

Totally Nuts: Circular Biobased Thermosets from Cashew Nutshells

Biodegradation Coatings Stahl

Green Hub: Information hub value chains green residual flows

Acceleration of nature-inclusive area development

Reflow

Biobased Insulation – Lifespan Determination (BILD)

Setting up and performing biodiesel trials in a coaster ship

Mythic

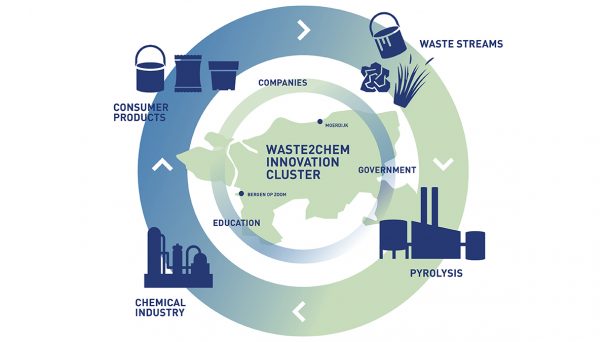

PyroCHEM: Waste2Chem Innovation Cluster

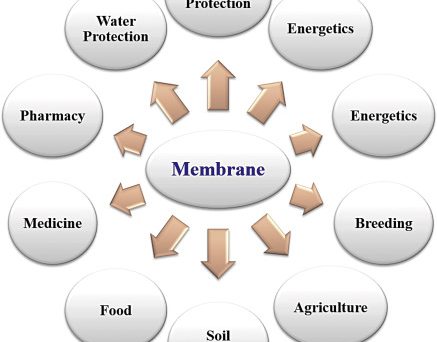

Membrane Technologies

Flestic

Direct extrusion of PHA-rich biomass

Production of bioplastics from residual streams (WoW! Capitalisation)

Powering Agrifood

Smart Circular Bridge

Fungal Colourants

Learning Network Biobuilders

Orange in the Sea

Amino Acids!

Building on Mycelium

Follow-up S4G

Colour Application Centre

Making disposables disposable

Making shipping more sustainable (Russia – Benelux)

Zircular Seaweed food

Extraction of pectins from onion skins

Growing Leather

Learning Community Renewable fuels

PHA accumulation capacity of Sewage Treatment Plant

NACO – Zero Waste Collective Oosterhout

Bio Iso (RAAK MKB)

Design with RRM (rapidly renewable materials)

Resin biodegradation

Biobased gadgets

Biobased foam

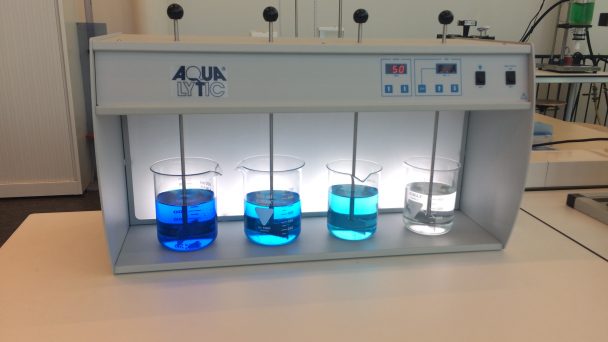

Biobased flocculants for water purification

Viberscrete – biobased concrete

Innovation Traineeships

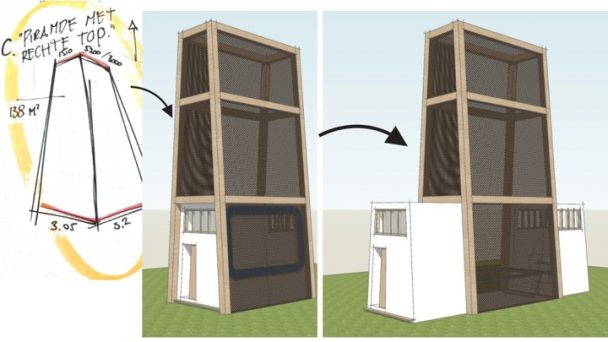

Building light

BioADD

CurCol

Learning community

Professors’ platform Biobased Economy

Porter’s lodge Delfland

Smart Circular Bridge

Biobased, circular Christmas bauble with packaging

Mycelium boards

Coloring Mycelium

Back to the Materials of the Future

National Biobased Database

Structural Health in Biobased Constructions

Beauti-Fully Biobased Fibers

Coffee Silverskin Biomass Utilization

Sustainable solid biofuels

Biobonding: Improved biocomposites

ZCORE (from Seaweed to COating Resin applications)

Cashing cashew

Material research for 3D printing

Seaweed Sterols

Onion deserves more

Circling in construction

Biomass flows in the province of South Holland

Circular Bio-based Construction Industry (CBCI)

Biodegradability of biopolymer and biopolymer composites

BBM+

Opportunities for composting in Brazil

Stadsjutters Breda

Innovation tables

Tomatozyme

MAA’s from algae

Sensor wise Biobased

Pyrolysis Experimental Garden South

Grassification

REFAWOOD

Valuable ONION

Biobased Network

Living Lab Biobased Brazil

Biopolymer Application Center

Borderless Biobased Education

Living Colors

Mycelium

BioCOLOUR

BioCannDo

Blue Chain

WOW!

Green Growth

Biobased Challenge

Biobased bridge

Pure Nature: 100% Biobased

National Biobased Knowledge Network