A mushroom ‘root network’ that acts as a natural glue to bind biomass? That is the basis what it is all about

is at the Mycelium Lab at the AKV St. Joost in Den Bosch. The lab is run by CARADT and Centre of Expertise Biobased Economy. Researchers and students work here on a daily basis on mycelium research. An additional advantage of this location at the art academy is that not only chemistry students work with mycelium, but art students also come into contact with this completely natural material. A multidisciplinary work environment, in other words!

Various organic residual streams such as straw, sawdust or other agricultural waste can be used as nutrient media for mycelium. The production of these composites has a relatively low energy consumption because mycelium grows at low temperatures (25- 30°C). For example, producing mycelium foam consumes almost ten times less energy than producing Styrofoam. Other advantages are that mycelium biocomposites are completely natural, non-toxic, biological materials that can be grown locally and composted after use. All that is needed is a better grip on the growth conditions and research into the material properties for applications in the construction industry, for example. The Centre of Expertise Biobased Economy is working hard on this.

BUILDING WITH MYCELIUM

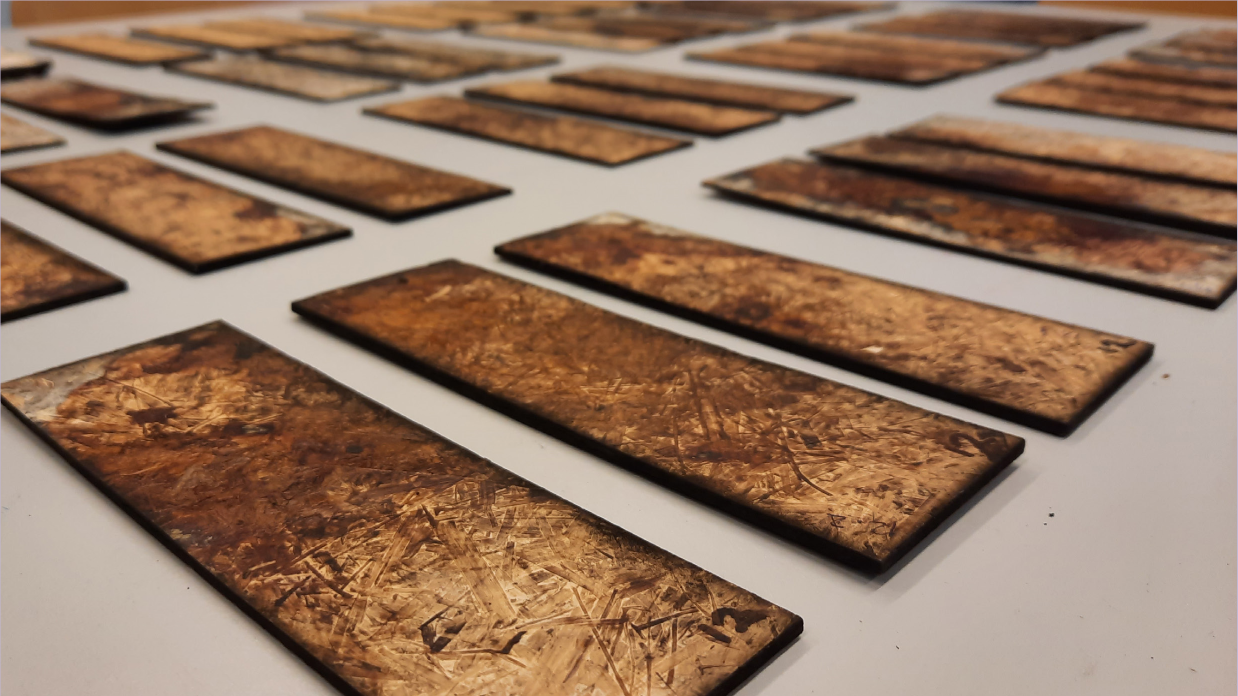

A nice example of a project carried out in the mycelium lab is the KIEM HBO Mycelium boards project. The goal is to achieve the maximum bending strength of mycelium boards. For this, through testing and research, the perfect process parameters, such as temperature, pressure and time, must be established. But how is the sheet material actually made in the first place? Ilaria la Bianca, researcher Lectorate Biobased Building explains, “By growing the mycelium through fibers, a composite material can be obtained. The composite is then heat-pressed to make sheet materials. These board materials have the potential to replace conventional toxic board materials, such as MDF. That’s what I like about this project.” The results of this project are already known. For example, it appears that a combination of mycelium and fibers results in stronger board materials than with fibers alone. Moreover, mycelium boards grown on straw exhibit a flexural strength of 16 MPa. Pretty close to MDF, which exhibits a flexural strength between 16 and 35 MPa.

FUNGAL COLORANTS

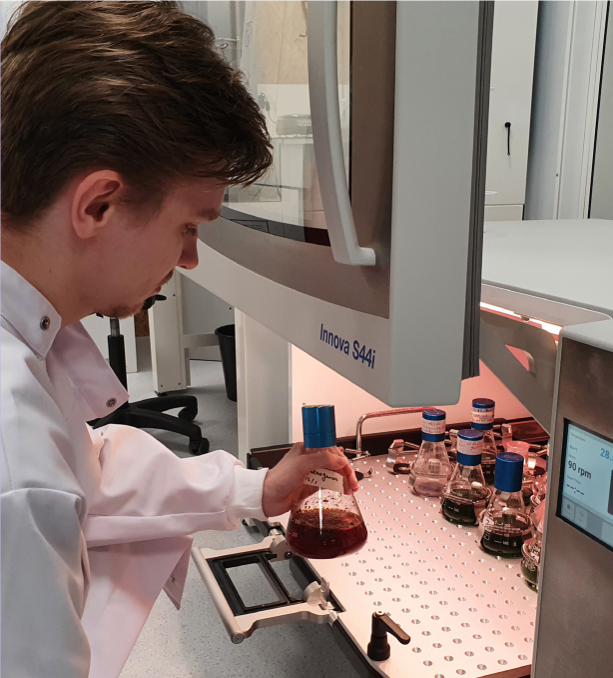

Another project that illustrates the type of research at the Mycelium Lab is Fungal Colourants. Colors are an essential part of human lives, as they can influence the final appearance of many products. A wide variety of choices can be influenced by the colors presented to us, for example in the food industry, product design, textiles etc. In the project Fungal Colourants, the possibilities of biobased colors from fungi are investigated. A more sustainable alternative than synthetic dyes. Ruben is a Biology & Medical Laboratory Research student and works on this project daily in the mycelium lab. ” I am mainly concerned with optimizing dyes using fungi. The Mycelium Lab is an innovative environment in which I can work and I also get a lot of freedom, which I like”.

Do you have questions about the projects within the Mycelium Lab, do you have ideas for a project, or are you curious about the facilities? Then please contact Ilaria la Bianca.